Pick & Place

Yaskawa Belgique Par applications Pick & Place

Vue d'ensemble

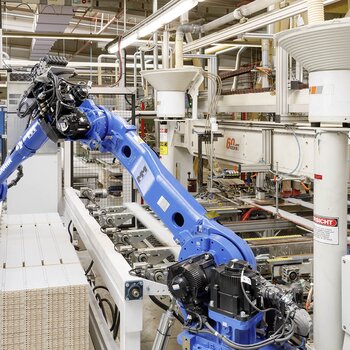

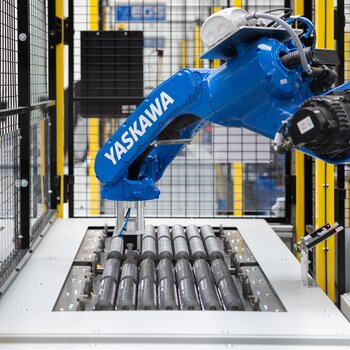

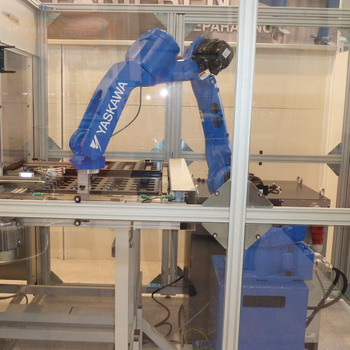

Pick & Place and Bin Picking with Motoman Robots

A pick-and-place robot is used to automate the process of picking up objects and placing them onto a surface in a set position and orientation. This action is frequently used to sort or stage products in a specific array for a downstream process, such as trays or cases, where fixed machinery or another robot can properly handle the products. Typical pick & place jobs are used for high speed picking, collating, part-transfer, singulation, sorting and inspection. In many cases, parts are coming along a conveyor belt, and the pick & place motion helps to sort or arrange the parts into a certain order at the place location.

Pick and Pack is a variation of Pick & Place, used on Packaging, where the placing motion is more complex to fill containers, boxes or crates. Some people say PPP - Pick, Place and Pack. Terminology is not standardized in this field.

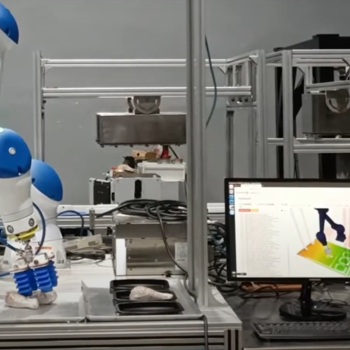

"Bin Picking" is an emerging Robotic Piece Picking Technology involving 3D Vision.

Speed and Throughput

All Pick & Place applications have the same target in their specification book - high throughput and low cycle times! Picking & Placing is a demanding job for robots. Not a space for unreliable toy manipulators. Motoman Robots are rigid and stable enough to do the job 24/7, without drive overheats, gearbox brakedowns or bolts and arms flying around after some weeks....

Motoman Robots and Products for Picking and Placing

For high speed picking, collating, part-transfer, singulation, sorting and inspection, robots range from 2kg payload capacity to 10kg with cycle-times as high as 150 pick cycles per minute are common. Our families of pick-and-place robot models includes serial-linked articulated arms with 5- or 6-degrees of freedom, delta-style parallel arms with 4 degrees of freedom, and SCARA style 4-degree of freedom arm.

Pick&Place with Delta Robots (MPP3 Series)

In terms of speed, nothing can beat our Delta Robots (MPP3H, MPP3s), speeding up to 4 pick cycles per second! If you place four of them into a row over a conveyor belt, equipped with MotoSight 2D Camera and MotoPick Software, you can achieve pick rates in the range of 600 to 800 parts/minute per picking line.

Pick & Place with SCARA Robots (SG Series)

SCARA-Robots (Horizontally Articulated Robots) are a good choice for up/downwards pick/place jobs on a flat table. Our brand-new SG-Series Robot Models (SG450, SG650) offer incredible axis speeds (R-Axis 3000 deg/sec.), capable to perform extraordinary high pick rates with attractive pricing.

5-Axis Pick & Place Robots (MPK Series)

Those articulated robots are typically ceiling mounted over a belt, similar to the Delta Robots, but more versatile in motion capability. They can pick and turn a part into the target placing location.

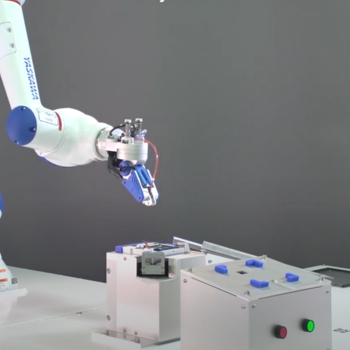

Pick & Place with 6-Axis Robots (MotoMini, GP Series)

Our Small 6-Axis Robots (MotoMini, GP7/GP8) are the choice when you need to turn/tilt the part during the picking motion, or where the pick direction is different to the place direction.

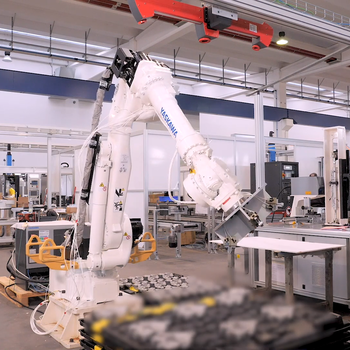

Larger 6-axis robots are used for more complex Pick&Place application, where the motion freedom of 6 degrees of motion is really required. Highest speed is not an issue here. For example in bin picking applications, where a machine vision software determines the individual target position and approach trajectory individually for each part, and where motion maneuvers are required from time to time to deal with bin walls and neighbour parts in the bin.

Pick & Place with Collaborative Robots (HC Series)

Cobots like HC10 cannot compete with those industrial robots in terms of speed, but they may have other benefits to be considered for Pick and Place applications - easy to use, fenceless installation or just assisting a human during his work. Our HC10 cobots are Hybrids, being able to switch from safe human interaction mode to faster speeds in phases where the operator is absent. Collaborative Robots (HC10) could be the choice in brownfield environments, saving installation space by avoiding fences. They are very flexible in terms of recoding and location flexibility. With Cobots you can realize do very attractive, smart and lean pick stations.

Conveyor Tracking and Line Tracking

A basic robot controller functionality for Pick & Place applications is Conveyor Tracking, which allows the synchronisation of the robot's trajectory with an external motion captured by an encoder, like a conveyor belt. The YASKAWA conveyor tracking function supports both line tracking (following a linear movement) and circular tracking (following a circular movement). Due to a very fast interpolation cycle and the design of our conveyor sensor board, the conveyor synchronisation is very sensitive and reacts perfectly even on slight velocity changes of the conveyor belt.

MotoPick Software

The MotoPick Software makes installation and programming of those picking lines absolutely easy, it does all calculations for you and decides automatically which robot is next to pick a part. All Motoman Robots can be combined with synchronized conveyor belts to perform high speed pick-and-place operations. Multiple robots, vision systems and multi-part conveyors are coordinated by a common software solution for accurate product sorting and package insertion. With our MotoPick Easy-to-configure Software, you can arrange up to 4 Pick&Place robots in a line behind a 2D vision camera identifying incoming parts on the belt, and distributing the picking job to the robots sharing the belt. Such picking lines can achieve really tremendous pick rates!

Robot Programming with PLC/IEC 61131 Function Blocks (MotoLogix)

Pick&Place Robots are often embedded or integrated into a PLC/Logic- or Motion Controlled machinery environment. If you are an OEM for High Speed Packaging Lines, with a lot of motion in your production line and just a few Pick/Place/Palletizing robots here and there, your PLC Programmers will like our PLC-based programming tool Motologix. The Robot motion jobs are programmed completely by the PLC Programmer in his IEC-based Program Development Environment. Motologix provides all the PLC Function blocks required to control pick&place motion of the robot, including conveyor support. No need to dig out a robotic teach pendant or to learn a robot programming language.

Robotic Grippers

A crucial success factor for a successful robotic pick&place installation is the gripper. The extreme inertia of a fast robotic cycle may easily let a workpiece fly out of the gripper if not being properly fixed. Suction grippers are often used, sometimes supported by clever mechanical features to avoid the part flying away due to the extreme accelerations. Yaskawa can help you with an excellent network and expertise with suppliers of all kind of pneumatic, stepper-/servo electric or exotic gripper products. 3D printing technology is often used for gripper fingers or gripper housing design, in order to reduce weight, downtime and spare part replacement time.

Some collaborative grippers have been explicitly designed for safe Human-Robot Collaboration.

All MOTOMAN Robot-Gripper installations are easy to deploy - no matter if you benefit from our rich interfacing know-how, or from our Smart Series of Grippers, which is a smart initiative by Yaskawa for Plug&Play Grippers. Most of the 5-/6-Axis Motoman Robots have standard internal medial cablling inside the arm, helping you to avoid external cable dress packs. Yaskawa controllers support all kind of I/O, fieldbus or Wi-Fi communication to grippers, including Ethernet, Profinet, Profibus, Devicenet, Ethercat, IOLink. All teaching methods (Standard Teach Pendant, Smart Pendant and Hand Guiding) offer simple and quick methods to control grippers. Some force/position controlled grippers require parameter setting, some solutions are embedded in the robot's HMI for better convenience.

Machine Vision Systems (2D, 2.5D, 3D)

MotoSight 2D Vision

3D Bin Picking, Intelligent Picking, Deep Learning

Die Bin-Picking-Technologie ist sehr flexibel und hat sich in den letzten Jahren sehr stark entwickelt hinsichtlich Geschwindigkeit, Erkennungsintelligenz und einfache Installation.

- all parts in the bin are identical, part geometry is known before - sample parts can be trained in advance.

- different part variants in the bin, part geometry is known before - sample parts can be trained in advance

- different part variants in the bin, part geometry is not exactly known before - sample parts cannot be trained in advance.

Using High Tech like Bin Picking is fine, but it is not a "Must Have" where a more pragmatic solution would do the same job. Our Engineers will help you to find the best and most reliable picking solution for your use case. Sometimes it is possible to change the part presentation way upstream, allowing you to install a simpler technical solution, e.g. by storing parts in layers.

Pick & Place Part Feeding with Motoman Robots

Vibration Part Feeders are an innovative way to present parts or fasteners to a robot. In combination with smart feeders, small Robots like the MotoMini, SG400 or GP8 are an alternative to classical vibratory bowl feeders. This screw feeding method is not cheaper or faster than classical screw feeding, but much more flexible and stable - less tolerance requirements for the screws, faster setup without need of screw sample batches, and easily adoptable to screw geometry or tolerance changes.